The Board

Know your weapon

A custom QCD is built to your personal specifications, it can be dialed in to suit your physical build and surfing requirements. Whether you are ordering your first custom or a 4-board quiver for an Indo adventure, Todd can talk you through every step of the process.

The relationship between the shaper and surfer is a fundamental dynamic you simply don’t get with stock boards. World champions have benefited from Todd’s extensive experience, and you can too.

Call or e-mail to discuss your next board with Todd personally.

Specifications

Length

This is the overall finished length of your board. The general rule of measuring from the floor to your belly button doesn’t always hold true.

The best way to find out what length is best for you is to have a go on friend’s boards until you find what works. Below is a general guide based on a rider’s height and weight to help you select the best board length for you.

Size Guide:

| Board Length | Height (cm) | Weight (kg) |

|---|---|---|

| 37″ | 123 – 153 | 28 – 55 |

| 37.5″ | 130 – 155 | 30 – 55 |

| 38″ | 135 – 155 | 35 – 58 |

| 39″ | 137 – 158 | 38 – 58 |

| 38.5″ | 140 – 162 | 40 – 60 |

| 39.5″ | 147 – 165 | 42 – 72 |

| 40″ | 157 – 167 | 42 – 72 |

| 40.5″ | 160 – 173 | 55 – 85 |

| 41″ | 158 – 170 | 50 – 80 |

| 41.5″ | 165 – 179 | 60 – 90 |

| 42″ | 168 – 183 | 65 – 95 |

| 42.5″ | 170 – 190 | 70 – 100 |

| 43″ | 172 – 195 | 70 – 105 |

Nose Width

As the name suggests, this is the finished nose width of your board, including rail skins. A narrow nose is good for drop knee riding and is also highly maneuverable when riding prone, though too narrow will make the board unstable around the front of the board and cause you too catch a rail.

Board Length (inch) Rider Height (cm) Rider Weight (kg)

Width

The overall width of the board is generally determined by the type of waves you will be surfing. Wider boards work best in small, weaker surf as they provide more flotation to get you through the sections.

Narrower boards are suited to bigger, more powerful waves. This is due to the fact that in the heavier stuff, you are looking to control the force of the wave.

A good rule of thumb is to multiply the board’s length x 0.506 to get the width e.g. 41.5” x 0.506 = 21”

Wide Point

This is the distance from the nose to the widest point of the board. The distance from the nose will determine the overall look of the board and the template that will best suit the dimensions you have requested.

A high wide-point suits a wider nose and straighter, boxy template. This type of configuration is more suited to prone boards.

A lower wide-point works well for a medium to narrow nose board, with a little more curve in the template. Best suited to versatile and drop-knee boards.

Rails

50/50 – An even % blend between top rail (chine) and bottom rail. Best for smaller, lighter riders in small surf.

60/40 – 60% bottom rail and 40% top rail (chine). The original rail set-up and standard for riders in powerful surf.

Tail Width

Tail width plays an important part in the performance of your board. A narrow tail will make the board loose and easy to release for spins and quick turns.

A wider tail will pick up speed faster than a narrow tail, but is harder to turn. The width of the tail must also be wide enough to support the weight of your hips and legs.

If you are not sure about your tail width, a rule of thumb for the tail is to divide the length of the board by 2.33 e.g. 42”/ 2.33 = 18.25”

Performance Options

Channels

When holding a line in the face of the wave or jamming a hard turn, there is only a relatively small percentage of the board in contact with the water. The section of the board that is in contact with the wave is generally the back corner. In fluid dynamic terms the area in contact is called “wetted area”. Before the invention of the channel, the problem that faced shapers and riders alike was how to increase this wetted area?

1st generation riders like JP Patterson and Ben Severson helped design and pioneer the channel. The function of the channel is to increase the surface area of the slick exactly where its needed, thus increasing the wetted area.

Its mathematical fact that the shortest distance between two points is a straight line. If you draw a curve between those same two points, the distance increases. If we take that example and apply it to the channel, the greater we draw the curve (or in the Bodyboard’s case, the deeper we sand the curve) the greater the distance between the two points. This distance equates to surface area.

By placing the channel close to the rail and in the back corner of the board, this has enabled shapers to increase the wetted area in that section of the board, maximizing contact with the wave. This has increased the riders ability to hold a higher line on the face of the wave and to apply more power to turns.

Another function of the channel is that it directs the flow of water along the edge of the rail. A good example of this is to picture a fast flowing river. If you were to place a flat bottom board on top of the water and against the flow, then turn the tail from left to right, the board would turn relatively freely. If you were to do the same thing with a board featuring channels, there would be more resistance to the turns as the water is now flowing up through the channels.

The same thing happens with the channel in the face of a wave. As the rider and board are traveling against the flow of the wave, the water is directed through the channel, acting somewhat like a fin and further enhancing the riders ability to maintain a higher line and greater edge control.

Channels can be overdone. Too deep and the board will grip too much causing a loss in speed and a possible trip over the falls as a result of being caught too high up on the wave face. The same can be said about channels that are too wide. Too wide and too deep and your board will go lie like a car with square wheels. The positioning of the channels is just as critical. If the channel is set too close to the rail, this can distort the rail line. If the channel is set too far from the rail, the channel will not function as intended.

As each QCD board is shaped by hand, the channel placement is completely precise on every board. We offer two channel designs, tested extensively by the world’s top riders in the most intense waves possible. Each has a specific benefit to improve the performance of your board.

Slot Channels

A narrow, deep channel design with an optimum contour for larger, heavier surf.

Graduated Channels

Smooth, shallow channel design with a wider profile for hold in small to medium size surf.

Tails

Bat Tail

Bat Tails work best in waves over 2-3 feet and are based on two principles:

1. The Bulb

By increasing the surface area though central tail area of the board, the weight of the rider is more evenly distributed. This helps to reduce body drag during take offs and on speed drives down the line.

2. The Wings

Each wing of the bat tail design is like a mini crescent tail. By positioning the tips of the wing at a point shorter than that of the bulb, this effectively shortens the length of the rail making the board looser, perfect for quick spinning moves around the pocket. When turning both the bulb and wing come into play as force is applied to both areas from the riders hips as they draw a smooth line through the turn. It is here that the design of the bat tail is critical. If the tail design causes the rail to be too short, then the board can spin out.

Todd has experimented with countless bat tail configurations and through feedback from the world’s top riders QCD offers two variations of the design that work.

Gullwing Tail

This tail is the best of both worlds, give you what you want out of a bat tail but still giving you the feel of a crescent tail.

Square Bat Tail

The squared bulb on this tail releases quicker for spins and transitional turns in and around the barrel.

Round Bat Tail

The full rounded bulb on this design gives maximum planning surface for all out speed, both at the take off and down the line.

Clipped Crescent Tail

The clipped crescent works in all surf conditions and features a symmetrical arc cut on a predetermined angle into the tail end of the board. The top of the tail provides the prone rider with a comfortable recess in which the rider’s hips and legs are unrestricted from movement.

The tail blocks are the pivot points for bottom turns and hard carves. If the blocks are too wide, the surface area of the block can offer too much resistance causing the tail to slide out. If the blocks are too small, the tail can dig in causing the board to bog and loose speed.

Todd shapes each clipped crescent tail individually, with the optimum sized ratio of tail arc to block width. The clipped crescent is versatile and works well for the part-time DK rider. The back foot of the DK’er can be forced into the top corner of this tail for more direct control in the turns and snaps.

DK Crescent Tail (full)

Purpose built for the DK brigade, the DK crescent features smaller tail blocks and a larger arc radius. When prone riding, the rider relies on their legs to assist in the turn. The DK’er doesn’t have that luxury and must drive harder off the tail block and lower rail to hold an edge throughout the turn. In this case a smaller tail block is preferred to increase the penetration into the wave face. The larger arc allows the tail to release quickly once back foot pressure is relaxed, which enables the DK’er to bring the tail back around after heavy snaps.

Stringers

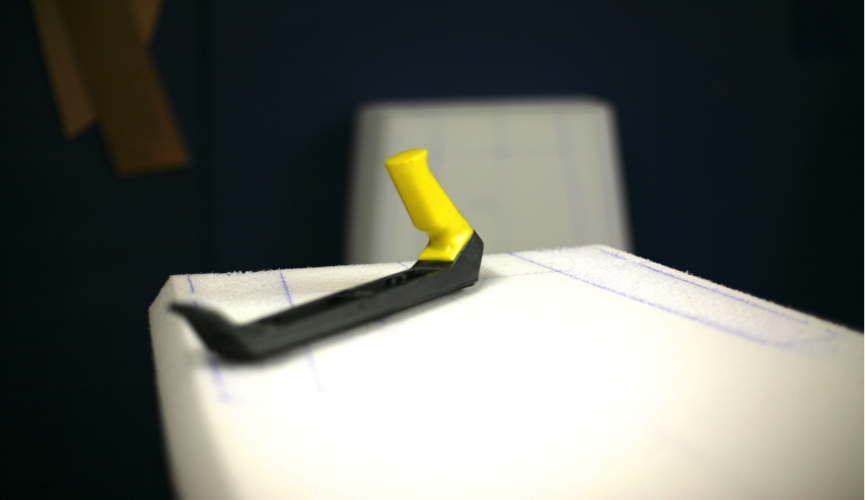

Flex-Tech Stringer System

With QCD stringer technology the Flex-Tech stringer is set into the center of the boards core. The main principle of the Flex-Tech stringer lies in the flexural properties of the tube itself. When the rider pulls up on the nose of the board, the upward force is transferred through to the stringer. As the tail of the stringer is centrally anchored in the board, only the front of the stringer bends to conform to the shape of the board.

This creates tension between the front and rear ends of the stringer, an action that is encountered during most turning manoeuvres. Once the rider releases the pressure from the front of the nose, so to is the applied pressure released from the stringer. This causes the stringer to instantly recoil back to its straight profile and further enhances the board’s ability to project down the line.

Flex-Tech stringers also have the added benefit of helping to maintain a flat rocker profile.

ISS™ The future of flex

More info to come on these bad boys.

QCD Flex-Tip Stringer System

Exclusive to QCD, The Flex-Tip Stringer is the answer for those riders who demand the integrity of a stringer but still want regular nose flex. This unique attribute is achieved with the technology of our precision milled Flex Hinge Constructed from a one piece durable laminated plastic the Flex Hinge is specifically designed to allow for optimum flex in the nose of the board.

Another feature of the two part Flex-Tip Stringer system is that the rear section of the stringer is shorter than a regular stringer, which makes it stronger as a result. This stringer is suited to cooler waters and for a guy who wants that worn in feel first surf.

QCD Flex-Tech and Flex-Tip Stringers are constructed from the finest grade composite fiber.

With a wall thickness of 1.5mm, the stringers facilitate just the right amount of flex. Both single and double stringer options are available.

Please Note: Tech-Flex and Flex-Tip Stringers will not prevent creasing.

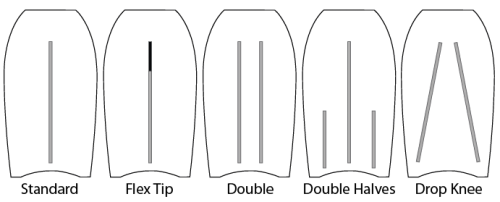

Stringer Options

Standard stringer.

The standard stringer set up for all round use and performance.

Double Standard Stringers.

For guys who like a stiffer board and a nice rigid feel. Perfect setup for warmer waters and or the heavier rider wanting something a little stronger in a board.

Flex-Tip Stringer (PP only)

A great setup for cooler waters and for the perfect worn in feel first surf, the smaller lighter rider

who wants a stiff board but can still get the flex at the nose they need.

Double Halves Stringer.

This combo is a setup between the single and double stringer, with X2 half stringers set at the tail is keeps the tail area nice and stiff with very minimal flex which helps generate speed down the line. The way to go for Indo missions and summer day fun. It gives you a great balance of flex.

DK Stringer.

This set up is used by a few 100% dedicated DK riders, with some going the opposite with the stingers

closer together at the tail. The reason for the angle of the stringers is to keep the board stiff at the impact sites being mostly the back knee, it also helps minimise the twist DK riders seem to get in a board.

ISS™ Stringer, the future of flex

With the option to change out the stringers in your board depending on the water temp and wave conditions you can’t go wrong with this setup.

Mesh

Tech Flex Mesh

A diamond shaped plastic weave, Tech Flex Mesh is thermo-fused in between the boards core and Surlyn™ bottom. The uniform spaces of the mesh enable the core to bond directly to the Surlyn™ producing a unique structural advantage that not only stiffens the board with minimal weight increase, but changes the pre and post stress profiles of the boards two lamination stages.

To equalize the increased tension the mesh causes after bottom lamination, more tension must be applied during the deck application. By balancing the tension between the two opposing surfaces, two things happen:

1. The board has a flat rocker profile

2. The board’s recoil/ memory properties are increased

Another advantage of the Tech Flex Mesh is that the layer covers the entire bottom surface of the board, delivering a more even flexural nature to the board.

Tech Flex Mesh stiffens both Dow™ PE and Pactiv™ PP cores to a medium level. We recommended either our Tech Flex or Flex-Tip stringer system for maximum board life.

Contours

Elbow Pads

A full length, slim-line foam insert, fused in between the deck and core. The pad helps to protect the core by absorbing repetitive elbow impact in much the same way the soft foam inner of your shoe cushions your feet from the harder rubber sole. The contoured shape of the panel is designed to lock in the rider.

Deck Bulbs

Raised nose grips placed on the top of the core, under the deck skin, to fit perfectly in the palm of your hand.

Slick Bulbs

Raised nose grips hand shaped into the corners of the Surlyn™ bottom, ergonomically formed for fingertip control.

ECS – Ergonomic Contour System

Ergonomics is the applied science of equipment design intended to maximize productivity by reducing fatigue and discomfort. That’s the technical explanation, so in simple terms it means that Todd and Jarrod have come up with several deck contour configurations that improve your grip, lock your body into position and look damn sexy!

We’ve got half contours for the elbows, forearms and hands. With the full contours giving you all that, plus comfort and control for the hips and lower torso.

All contours are hand shaped and perfectly adapted for an individual fit. With or without elbow pads, ECS is the next level in custom control.

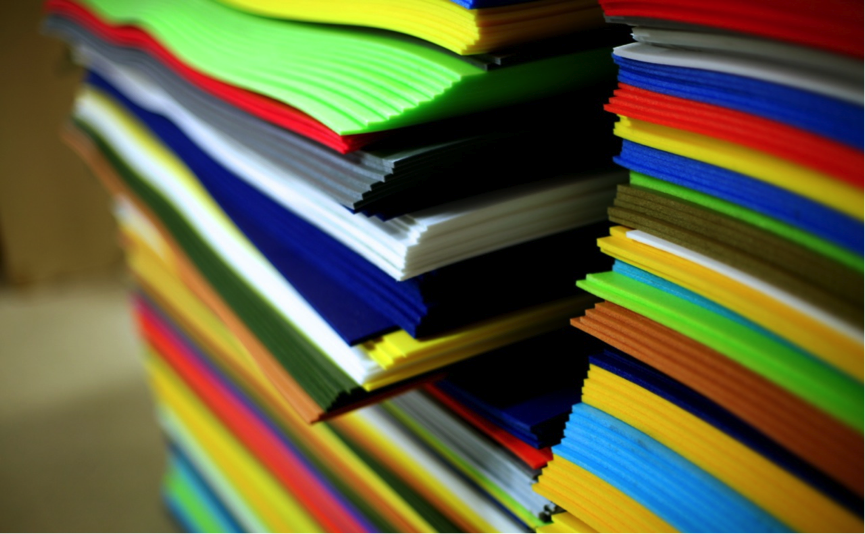

Materials

Cores

Polyethylene (PE)

PE has been the industry standard core for over 30 years. First used due to its flexible nature, relatively low cost and ease of heat lamination with other PE based materials, the performance attributes of PE only came to the fore when combined with the Surlyn™ slick bottom.

A triple layered sandwich construction of 8lb PE deck, PE core and Surlyn™ revolutionized performance bodyboarding in late 80’s. This same construction combo is still used today today. The flex attributes of PE allow the rider to contort and manipulate the board to harness the power of the wave and transfer that power into projection. As the rider drives into a bottom turn, the downward gravitational force of the rider is opposed by the upward draw of the wave.

The board is subject to these forces in much the same way as a pumpkin seed is subject to opposing pressure when squeezed between the thumb and forefinger. Equal pressure will keep the seed in a seemingly stable state, but by slightly concentrating the pressure towards the back of the seed the net result causes the seed to shoot forwards.This same “pumpkin seed” effect can be applied to the projection of the bodyboard. The projection is a result of the release from the opposing forces and the boards ability to instantly recoil to its pre-set flat rocker profile.

PE is the core of choice for those who surf in colder water climates and riders who like a little more flex.

Kinetic Core™ Polypropylene (PP)

At a comparable density to that of PE = 2.2 pcf (pounds per cubic foot), PP is too stiff for use as a bodyboard core. This has allowed the foam techs to reduce the density by over 15% to 1.9pcf and still produce a superior, stiffer blank. The reduction in density also reduces the finished weight of the board considerably.

The construction technique of heat laminating outer skins to the PP core is far more intricate than that of PE. As PP does not directly bond with PE, various substrates must be used to create multi-layered skins for this specific purpose.

The PP core will tend to power through choppy surf due to it’s stiff nature. Perfect for warm water climates and water temps, PP core is for riders who like a more rigid platform for today’s high performance manoeuvres.

NRG+™

Developed using cutting-edge expansion cell technology, NRG+ Core™ is a cool water core specifically formulated to meet key performance characteristics as demanded by our worldwide team of the sports elite riders. Now with the added strength of a 1/4” Kinetic PP deck underlay, NRG+ Core™ gives you an even better mix of flex, recoil, projection and pop

Tension Tech™

TensionTech™ takes advanced sandwich composite principles and applies them to Kinetic™ and NRG™ cores for next level recoil and projection. A bi-axial Mesh layer is thermo-fused between 2 crosslinked polypropylene skins. The resulting Mesh Fusion Layer is then laminated directly to the core, under the deck, greatly increasing the boards tensile and compression strength. The dynamic properties of TensionTech™ allow us to build a board that’s thinner, stronger and stiff, but at the same time, possesses incredible elastic flex for instant recoil and spring-like projection.

Slick

Surlyn™

The same company that brought us Teflon™, Nylon™ and Lycra™, invented the Surlyn™ resin. Initially used as a cover for golf balls due to its unique abilities to resist cutting and abrasions from golf club impact, some bright cookie at Morey Boogie decided to try it as a bottom skin on bodyboards.

With its rubber-like properties, Surlyn™ provided the Bodyboard with a tough slick skin with precise flexural stiffness. This worked in perfect harmony with the boards core and top skin and gave the boards what they had been missing, rigidity. With rigidity came speed, which propelled the Bodyboard from a soft toy into a high performance wave-riding vehicle. The rest, as they say, is history.

Todd uses Surlyn™ on all QCD boards. Nothing else comes close.

Impact resistance

IXL Protective Guards

Two areas of the board that are subject to impact damage are the nose and tail seams. The constant pulling up on the corner of the nose by the rider and damage as a result of leash wrap can cause the nose seam to deteriorate and split.

The tail seam also gets a battering from knee drive pressure during duck-diving, not to mention abrasion and impact to both seams from contact with sand, rocks and other unfortunate collisions.

By heat fusing an impact resistant, IXL (crosslink) foam, directly to the Surlyn™ bottom and then wrapping the deck skin over the nose and tail contours, QCD creates the IXL Protective Guard layer.

Not only does the layer help absorb the impact and boost the seam strength, the direct bond to the Surlyn™ greatly improves the seal helping to prevent water from penetrating the core.

IXL Inner Rails

All QCD customs are double railed with an inner strip of super fine celled, 4mm 8lb IXL crosslink PE and an outer strip of NXL 8lb 4mm PE.

The IXL inner rail forms a supreme bond to the boards core, deck skin and, Surlyn™ bottom, encasing the core with a virtually waterproof barrier. Now available in multiple colours on request.

Decks

Todd uses NXL 8lb 4mm PE deck skins on all QCD customs. For PP decks 8lb 4mm NXL PE/Film/Black PP Substrate is used.

The factory constantly produces the finest grade skins available and although it is more expensive than other grades of PE skins, QCD is only interested in making the best boards, not the cheapest.

NXL PE or PP backed Substrate 8lb has a tight, uniform cell structure and bonds perfectly to Dow, PP and EFC cores via our custom built Buzz-Tech laminator. Combined with Surlyn™, these boards are the ultimate boards on the market.

Rails

All QCD customs feature NXL 8lb 4mm PE outer rail skins. Stiff and strong, Todd hand laminates the rail strips then accurately trims them flush, perfectly in-line with the chine and slick angles to form precise edges. Then using the rolling technic to seal the edges for a superior finish and feel.

header photo – Alex Gibson